|

|

|

| |

|

一、DIN2093(GB/T1972)碟形弹簧规格

|

|

|

|

|

|

| 发布时间:2010.03.02 新闻来源:www.discspringsource.cn 浏览次数: |

| |

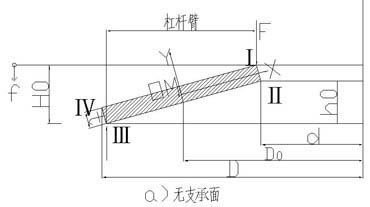

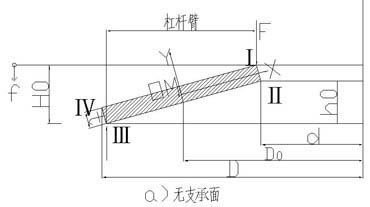

碟形弹簧是截面为锥形的,可以承受轴向载荷(静载荷或交变载荷)的一种弹簧,其特点是“在最小的空间内以最大的载荷工作”(‘ Maximum force in minimum space ')。普通标准碟形弹簧的外径从 8.0mm 到 600.0mm ,厚度从 0.2mm 到 40.0mm 。普通标准碟形弹簧的规格见下表。碟形弹簧的表面处理方法有发蓝、磷化、电镀、电泳和机械镀锌等。 碟形弹簧的特性线 碟形弹簧组件 Disc spring stacks 碟形弹簧的组合方式有对合、叠合和复合等,其组件的特性线见下图。 碟簧组件的外观 碟簧组件的特性线。

| DIN2093(GB/T1972-2005) |

| 序列 A D/t≈18; h0/t≈0.4 E=206 000N/mm2 ; μ=0.30 |

| 序号 |

D/mm |

d/mm |

t(t′)/mm |

h0/mm |

H0/mm |

f≈0.75h0 |

Q/KG/1000片 |

| f/mm |

(H0-f)/mm |

F/N |

σ om/ N/mm2 |

σⅡ、σⅢ/N/mm2 |

| A1 |

8 |

4.2 |

0.4 |

0.2 |

0.6 |

0.15 |

0.45 |

210 |

-1200 |

1220* |

0.114 |

| A2 |

10 |

5.2 |

0.5 |

0.25 |

0.75 |

0.19 |

0.56 |

329 |

-1210 |

1240* |

0.225 |

| A3 |

12.5 |

6.2 |

0.7 |

0.3 |

1 |

0.23 |

0.77 |

673 |

-1280 |

1420* |

0.508 |

| A4 |

14 |

7.2 |

0.8 |

0.3 |

1.1 |

0.23 |

0.87 |

813 |

-1190 |

1340* |

0.711 |

| A5 |

16 |

8.2 |

0.9 |

0.35 |

1.25 |

0.26 |

0.99 |

1000 |

-1160 |

1290* |

1.05 |

| A6 |

18 |

9.2 |

1 |

0.4 |

1.4 |

0.3 |

1.1 |

1250 |

-1170 |

1300* |

1.48 |

| A7 |

20 |

10.2 |

1.1 |

0.45 |

1.55 |

0.34 |

1.21 |

1530 |

-1180 |

1300* |

2.01 |

| A8 |

22.5 |

11.2 |

1.25 |

0.5 |

1.75 |

0.38 |

1.37 |

1950 |

-1170 |

1320* |

2.94 |

| A9 |

25 |

12.2 |

1.5 |

0.55 |

2.05 |

0.41 |

1.64 |

2910 |

-1210 |

1410* |

4.4 |

| A10 |

28 |

14.2 |

1.5 |

0.65 |

2.15 |

0.49 |

1.66 |

2850 |

-1180 |

1280* |

5.39 |

| A11 |

31.5 |

16.3 |

1.75 |

0.7 |

2.45 |

0.53 |

1.92 |

3900 |

-1190 |

1320* |

7.84 |

| A12 |

35.5 |

18.3 |

2 |

0.8 |

2.8 |

0.6 |

2.2 |

5190 |

-1210 |

1330* |

11.4 |

| A13 |

40 |

20.4 |

2.25 |

0.9 |

3.15 |

0.68 |

2.47 |

6540 |

-1210 |

1340* |

16.4 |

| A14 |

45 |

22.4 |

2.5 |

1 |

3.5 |

0.75 |

2.75 |

7720 |

-1150 |

1300* |

23.5 |

| A15 |

50 |

25.4 |

3 |

1.1 |

4.1 |

0.83 |

3.27 |

12000 |

-1250 |

1430* |

34.3 |

| A16 |

56 |

28.5 |

3 |

1.3 |

4.3 |

0.98 |

3.32 |

11400 |

-1180 |

1280* |

43 |

| , A17 |

63 |

31 |

3.5 |

1.4 |

4.9 |

1.05 |

3.85 |

15000 |

-1140 |

1300* |

64.9 |

| A18 |

71 |

36 |

4 |

1.6 |

5.6 |

1.2 |

4.4 |

20500 |

-1200 |

1330* |

91.8 |

| A19 |

80 |

41 |

5 |

1.7 |

6.7 |

1.28 |

5.42 |

33700 |

-1260 |

1460* |

145 |

| 90 |

46 |

5 |

2 |

7 |

1.5 |

5.5 |

31400 |

-1170 |

-1170 |

184.5 |

184.5 |

| A21 |

100 |

51 |

6 |

2.2 |

8.2 |

1.65 |

6.55 |

48000 |

-1250 |

1420* |

273.7 |

| A22 |

112 |

57 |

6 |

2.5 |

8.5 |

1.88 |

6.62 |

43800 |

-1130 |

1240* |

343.8 |

| A23 |

125 |

64 |

8(7.5) |

2.6 |

10.6 |

1.95 |

8.65 |

85900 |

-1280 |

1330* |

533 |

| A24 |

140 |

72 |

8(7.5) |

3.2 |

11.2 |

2.4 |

8.8 |

85300 |

-1260 |

1280* |

666.6 |

| A25 |

160 |

82 |

10(9.4) |

3.5 |

13.5 |

2.63 |

10.87 |

139000 |

-1320 |

1340* |

1094 |

| A26 |

180 |

92 |

10(9.4) |

4 |

14 |

3 |

11 |

125000 |

-1180 |

1200* |

1387 |

| A27 |

200 |

102 |

12(11.25) |

4.2 |

16.2 |

3.15 |

13.05 |

183000 |

-1210 |

1230* |

2100 |

| A28 |

225 |

112 |

12(11.25) |

5 |

17 |

3.75 |

13.25 |

171000 |

-1120 |

1140 |

2640 |

| A29 |

250 |

127 |

14(13.1) |

5.6 |

19.6 |

1.2 |

15.4 |

249000 |

-1200 |

1220 |

3750 |

| 序列 B D/t≈28;h0/t≈0.75 E=206000N/mm2 ; μ=0.30 |

| 序号 |

D/mm |

d/mm |

t(t′)/mm |

h0/mm |

H0/mm |

f≈0.75h0 |

|

| f/mm |

(H0-f)/mm |

F/N |

σ om/ N/mm2 |

σⅡ、σⅢ/N/mm2 |

Q/kg/1000pcs |

| B1 |

8 |

4.2 |

0.3 |

0.25 |

0.55 |

0.19 |

0.36 |

119 |

-1140 |

1330 |

0.086 |

| B2 |

10 |

5.2 |

0.4 |

0.3 |

0.7 |

0.23 |

0.47 |

213 |

-1170 |

1300 |

0.180 |

| B3 |

12.5 |

6.2 |

0.5 |

0.35 |

0.85 |

0.26 |

0.59 |

291 |

-1000 |

1110 |

0.363 |

| B4 |

14 |

7.2 |

0.5 |

0.4 |

0.9 |

0.3 |

0.6 |

279 |

-970 |

1100 |

0.444 |

| B5 |

16 |

8.2 |

0.6 |

0.45 |

1.05 |

0.34 |

0.71 |

412 |

-1010 |

1120 |

0.698 |

| B6 |

18 |

9.2 |

0.7 |

0.5 |

1.2 |

0.38 |

0.82 |

572 |

-1040 |

1130 |

1.03 |

| B7 |

20 |

10.2 |

0.8 |

0.55 |

1.35 |

0.41 |

0.94 |

745 |

-1030 |

1110 |

1.46 |

| B8 |

22.5 |

11.2 |

0.8 |

0.65 |

1.45 |

0.49 |

0.96 |

710 |

-962 |

1080 |

1.88 |

| B9 |

12.2 |

0.9 |

0.7 |

1.6 |

0.53 |

1.07 |

868 |

-938 |

1030 |

2.64 |

2.64 |

| B10 |

28 |

14.2 |

1 |

0.8 |

1.8 |

0.6 |

1.2 |

1110 |

-961 |

1090 |

3.59 |

| B11 |

31.5 |

16.3 |

1.25 |

0.9 |

2.15 |

0.68 |

1.47 |

1920 |

-1090 |

1190 |

5.6 |

| B12 |

35.5 |

18.3 |

1.25 |

1 |

2.25 |

0.75 |

1.5 |

1700 |

-944 |

1070 |

7.13 |

| B13 |

40 |

20.4 |

1.5 |

1.15 |

2.65 |

0.86 |

1.79 |

2620 |

-1020 |

1130 |

10.95 |

| B14 |

45 |

22.4 |

1.75 |

1.3 |

3.05 |

0.98 |

2.07 |

3660 |

-1050 |

1150 |

16.4 |

| B15 |

50 |

25.4 |

2 |

1.4 |

3.4 |

1.05 |

2.35 |

4760 |

-1060 |

1140 |

22.9 |

| B16 |

56 |

28.5 |

2 |

1.6 |

3.6 |

1.2 |

2.4 |

4440 |

-963 |

1090 |

28.7 |

| B17 |

63 |

31 |

2.5 |

1.75 |

4.25 |

1.31 |

2.94 |

7180 |

-1020 |

1090 |

46.4 |

| B18 |

71 |

36 |

2.5 |

2 |

4.5 |

1.5 |

3 |

6730 |

-934 |

1060 |

57.7 |

| B19 |

80 |

41 |

3 |

2.3 |

5.3 |

1.73 |

3.57 |

10500 |

-1030 |

1140 |

87.3 |

| B20 |

90 |

46 |

3.5 |

2.5 |

6 |

1.88 |

4.12 |

14200 |

-1030 |

1120 |

129.1 |

| B21 |

100 |

51 |

3.5 |

2.8 |

6.3 |

2.1 |

4.2 |

13100 |

-926 |

1050 |

159.7 |

| B22 |

112 |

57 |

4 |

3.2 |

7.2 |

2.4 |

4.8 |

17800 |

-963 |

1090 |

229.2 |

| B23 |

125 |

64 |

5 |

3.5 |

8.5 |

2.63 |

5.87 |

30000 |

-1060 |

1150 |

355.4 |

| B24 |

140 |

72 |

5 |

4 |

9 |

3 |

6 |

27900 |

-970 |

1100 |

444.4 |

| B25 |

160 |

82 |

6 |

4.5 |

10.5 |

3.38 |

7.12 |

41100 |

-1000 |

1110 |

698.3 |

| B26 |

180 |

92 |

6 |

5.1 |

11.1 |

3.83 |

7.27 |

37500 |

-895 |

1040 |

885.4 |

| B27 |

200 |

102 |

8(7.5) |

5.6 |

13.6 |

4.2 |

9.4 |

76400 |

-1060 |

1250 |

1369 |

| B28 |

225 |

112 |

8(7.5) |

6.5 |

14.5 |

4.88 |

9.62 |

70800 |

-951 |

1180 |

1761 |

| B29 |

250 |

127 |

10(9.4) |

7 |

17 |

5.25 |

11.75 |

119000 |

-1050 |

1240 |

2687 |

| 序列 C D/t≈40; h0/t≈1.30; E=206000N/mm2; μ=0.30 |

| 序号 |

D/mm |

d/mm |

t(t′)/mm |

h0/mm |

H0/mm |

f≈0.75h0 |

|

| f/mm |

, (H0-f)/mm |

F/N |

σ om/ N/mm2 |

σⅡ、σⅢ/N/mm2 |

Q/kg/1000pcs |

| C1 |

8 |

4.2 |

0.2 |

0.25 |

0.45 |

0.19 |

0.26 |

39 |

-762 |

1040 |

0.057 |

| C2 |

10 |

5.2 |

0.25 |

0.3 |

0.55 |

0.23 |

0.32 |

58 |

-734 |

980 |

0.112 |

| C3 |

12.5 |

6.2 |

0.35 |

0.45 |

0.8 |

0.34 |

0.46 |

152 |

-944 |

1280 |

0.251 |

| C4 |

14 |

7.2 |

0.35 |

0.45 |

0.8 |

0.34 |

0.46 |

123 |

-769 |

1060 |

0.311 |

| C5 |

16 |

8.2 |

0.4 |

0.5 |

0.9 |

0.38 |

0.52 |

155 |

-751 |

1020 |

0.466 |

| C6 |

18 |

9.2 |

0.45 |

0.6 |

1.05 |

0.45 |

0.6 |

214 |

-789 |

1110 |

0.661 |

| C7 |

20 |

10.2 |

0.5 |

0.65 |

1.15 |

0.49 |

0.66 |

254 |

-772 |

1070 |

0.912 |

| C8 |

22.5 |

11.2 |

0.6 |

0.8 |

1.4 |

0.6 |

0.8 |

425 |

-883 |

1230 |

1.41 |

| C9 |

25 |

12.2 |

0.7 |

0.9 |

1.6 |

0.68 |

0.92 |

601 |

-936 |

1270 |

2.06 |

| C10 |

28 |

14.2 |

0.8 |

1 |

1.8 |

0.75 |

1.05 |

801 |

-961 |

1300 |

2.87 |

| C11 |

31.5 |

16.3 |

0.8 |

1.05 |

1.85 |

0.79 |

1.06 |

687 |

-810 |

1130 |

3.58 |

| C12 |

35.5 |

18.3 |

0.9 |

1.15 |

2.05 |

0.86 |

1.19 |

831 |

-779 |

1080 |

5.14 |

| C13 |

40 |

20.4 |

1 |

1.3 |

2.3 |

0.98 |

1.32 |

1020 |

-772 |

1070 |

7.3 |

| C14 |

45 |

22.4 |

1.25 |

1.6 |

2.85 |

1.2 |

1.65 |

1890 |

-920 |

1250 |

11.7 |

| C15 |

50 |

22.4 |

1.25 |

1.6 |

2.85 |

1.2 |

1.65 |

1550 |

-754 |

1040 |

14.3 |

| C16 |

56 |

28.5 |

1.5 |

1.95 |

3.45 |

1.46 |

1.99 |

2620 |

-879 |

1220 |

21.5 |

| C17 |

63 |

31 |

1.8 |

2.35 |

4.15 |

1.76 |

2.39 |

4240 |

-985 |

1350 |

33.4 |

| C18 |

71 |

36 |

2 |

2.6 |

4.6 |

1.95 |

2.65 |

5140 |

-971 |

1340 |

46.2 |

| C19 |

80 |

41 |

2.25 |

2.95 |

5.2 |

2.21 |

2.99 |

6610 |

-982 |

1370 |

65.5 |

| C20 |

90 |

46 |

2.5 |

3.2 |

5.7 |

2.4 |

3.3 |

7680 |

-935 |

1290 |

92.2 |

| C21 |

100 |

51 |

2.7 |

3.5 |

6.2 |

2.63 |

3.57 |

8610 |

-895 |

1240 |

123.2 |

| C22 |

112 |

57 |

3 |

3.9 |

6.9 |

2.93 |

3.97 |

10500 |

-882 |

1220 |

171.9 |

| C23 |

125 |

61 |

3.5 |

4.5 |

8 |

3.38 |

4.62 |

15100 |

-956 |

1320 |

248.9 |

| C24 |

140 |

72 |

3.8 |

4.9 |

8.7 |

3.68 |

5.02 |

17200 |

-904 |

1250 |

337.7 |

| C25 |

160 |

82 |

4.3 |

5.6 |

9.9 |

4.2 |

5.7 |

21800 |

-892 |

1240 |

500.4 |

| C26 |

180 |

92 |

4.8 |

6.2 |

11 |

4.65 |

6.35 |

26400 |

-869 |

1200 |

708.4 |

| C27 |

200 | ,

102 |

5.5 |

7 |

12.5 |

5.25 |

7.25 |

36100 |

-910 |

1250 |

100 |

| C28 |

225 |

112 |

6.5(6.2) |

7.1 |

13.6 |

5.33 |

8.27 |

44600 |

-840 |

1140 |

1456 |

| C29 |

250 |

127 |

7(6.7) |

7.8 |

14.8 |

5.85 |

8.95 |

50500 |

-814 |

1120 |

1915 |

碟形弹簧补充规格

非常用碟形弹簧规格

DIN2093(GB/T1972)碟形弹簧介绍 |

| |

|